LINKUP 100 & 200 Series CCO wear plate is a bi-metallic plate, consisting of a mild steel base ASTM A36 ( EN10025-2 S235JR or JIS G3101 SS400), with a high alloyed wear- resistant cladding: Chromium carbide(Cr7C3), primary carbide volume ﹥50%, the micro-hardness up to HV1800. The mild steel base plate allows the product to be cut, bent, welded, bolted, or studded to existing structures. Physical Properties: Excellent abrasion resistance of the hardface layer, according to ASTM G65 the hardface outlasts mild steel by 20 times and 8 times than heat-treated steel. Bonding layer: the cladding layer penetrates the base plate about 0.8-1.8mm(350Mpa).

| Thickness | Hardness | Main Ingredient | Weld bead pattern | Process | Crack |

| overlayer: 3~26mm, base metal: 3mm~40mm | 57~65 HRC | C: 3.0~5.5%, Cr: 23~40% | straight, wave, zig zag | open arc welding submerged arc welding | evenly distributed cracks |

Special chemical composition or application can be customized

| Special chemical composition | Moderate impact resistant | Severe impact resistant | High temperature resistant |

| with Ni, Ti, V, Nb, B,W, etc | C, Cr, Mn | C, Cr, Mn, Mo, Ni | 600℃~900℃ C, Cr, Mo, Nb, W, V |

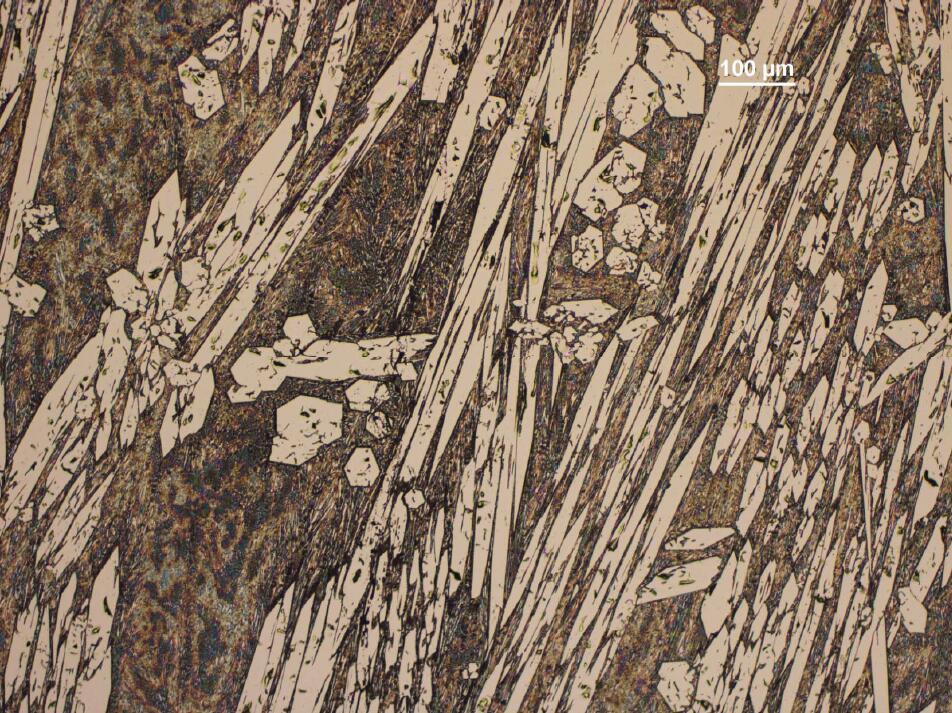

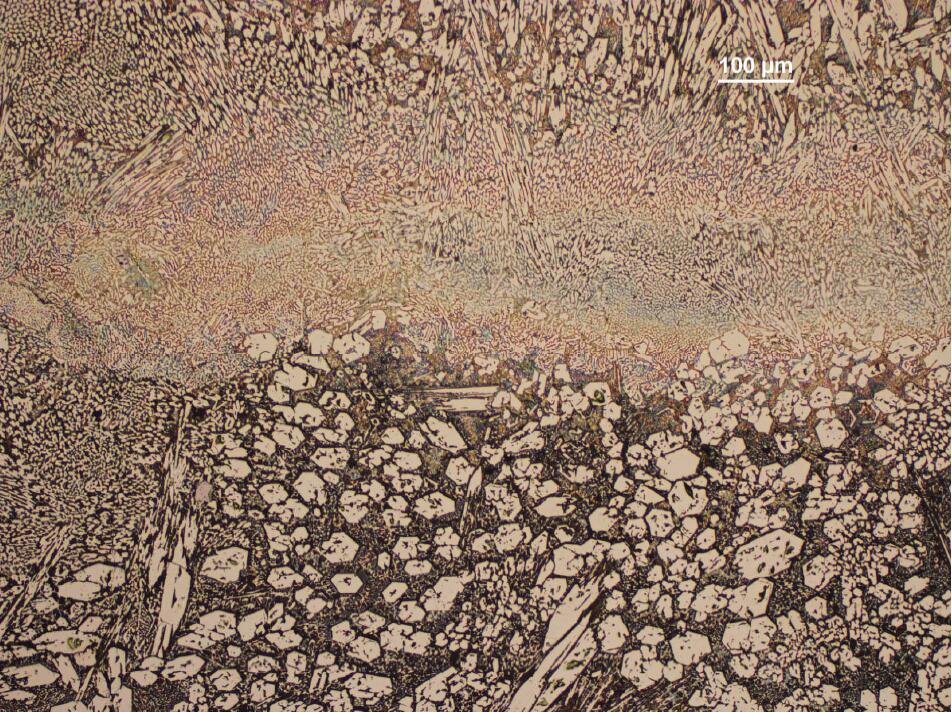

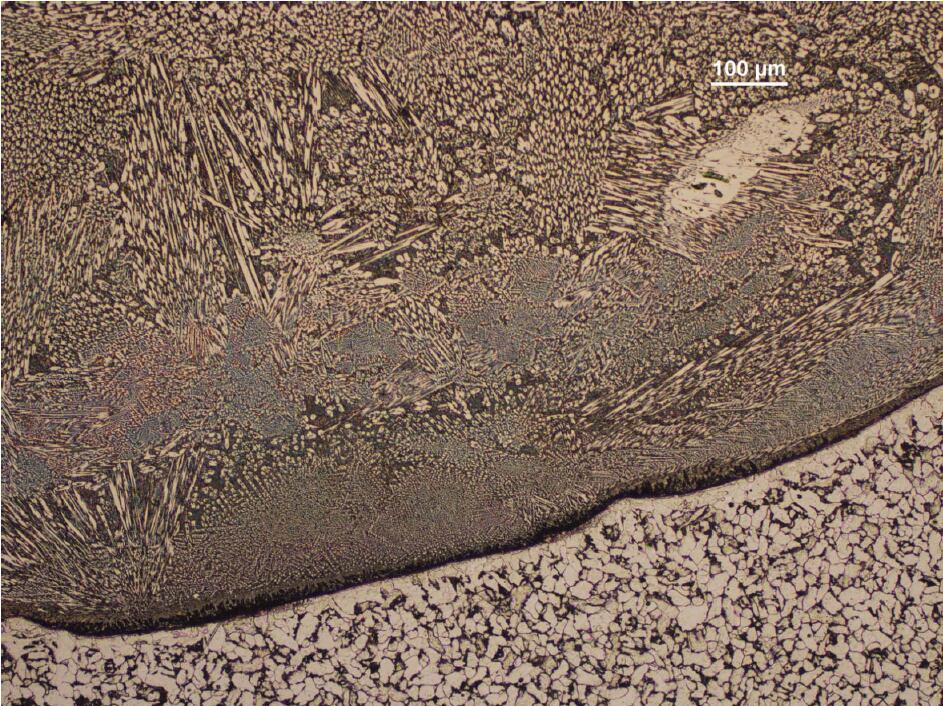

Microstructure analysis: Chromium Carbide, Magnification:100X,Etchant: 4% Nital + Kallings

Img.1 Middle of 2nd welding overlay Img.2 Boundary of 1st and 2nd weld overlay Img.3 Middle of 1st weld overlay Img.4 Base metal fusion line

Img.1 Middle of 2nd welding overlay Img.2 Boundary of 1st and 2nd weld overlay Img.3 Middle of 1st weld overlay Img.4 Base metal fusion line

Standard overlay plate sizes

| 1200*3000mm | 1400*3000mm | 1400*3500mm | 1500*3000mm |

| 2000*3000mm | 2100*3500mm | 2200*3600mm | other customized sizes |

Our CCO wear plates are widely used in the mining, power generation, cement, dredging, steel production, waste handling, glass production, and pulp and paper industries. Some specific applications include: